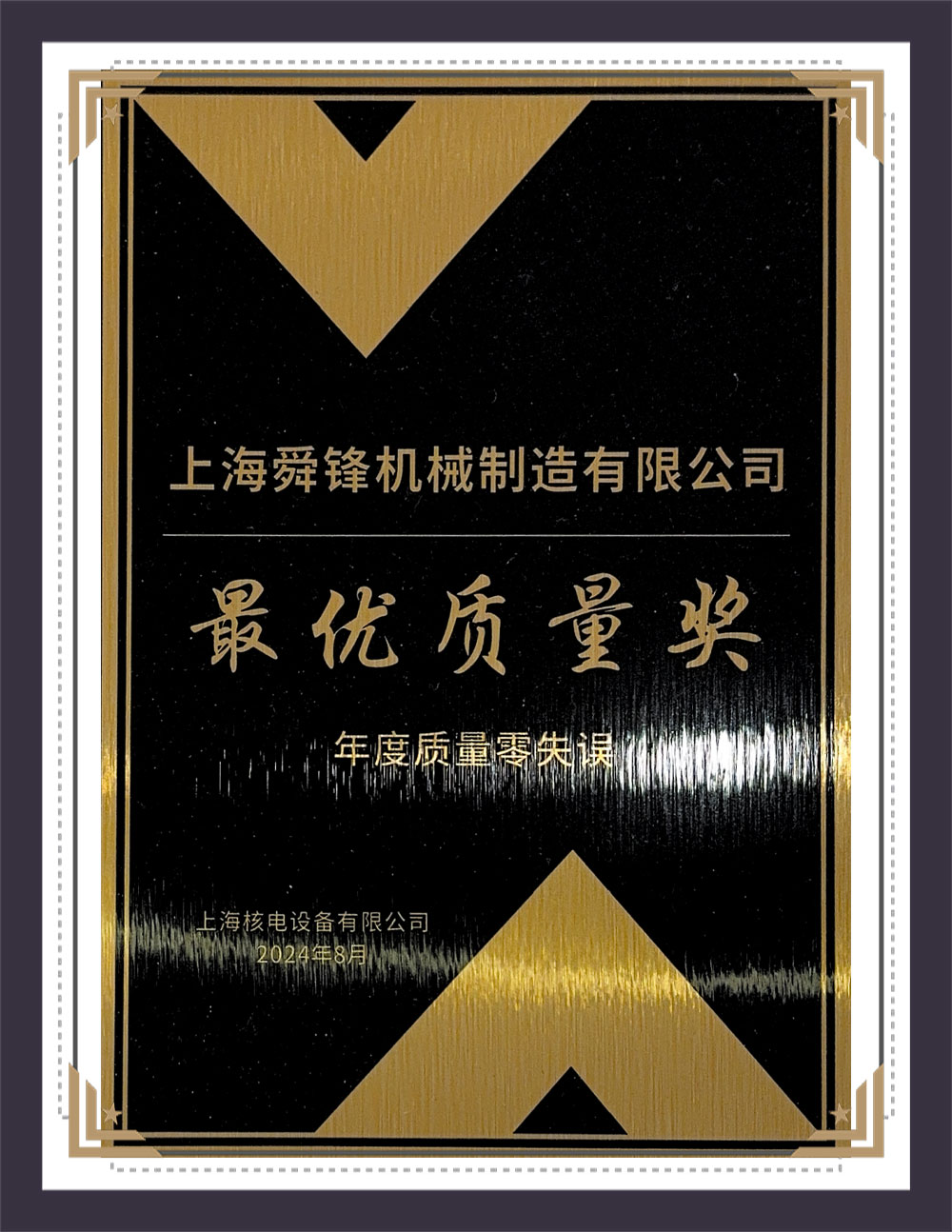

SUNFUN Group specializes in intelligent and sustainable industrial development. Driving quality advancement in manufacturing across China and the globe through technological innovation, we are committed to creating green value for a better human life.

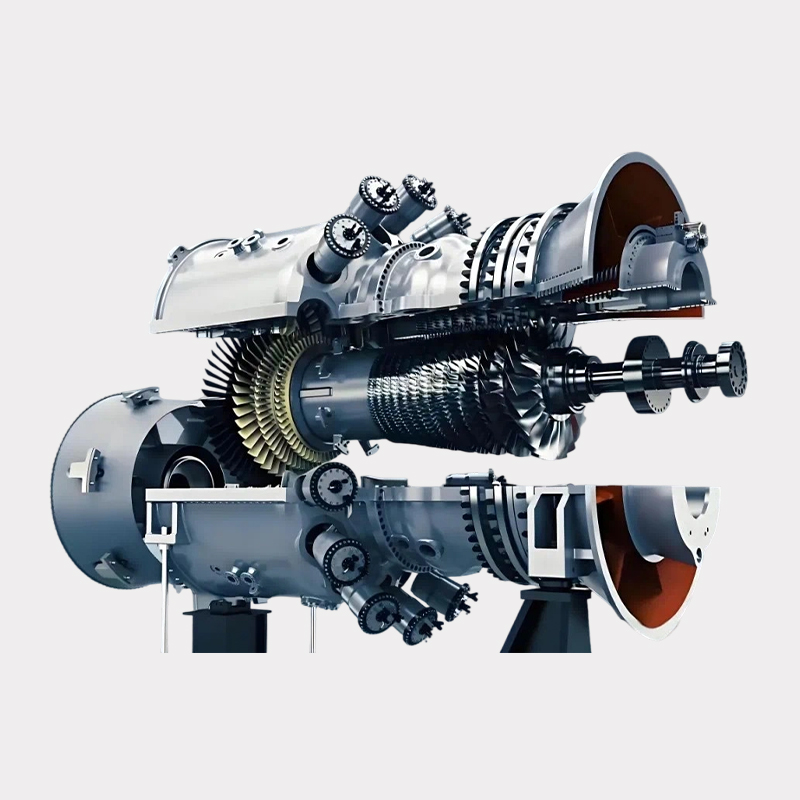

We have deep expertise in smart energy and smart manufacturing, consistently achieving breakthroughs in precision production. Our capabilities range from 0.001-mm precision machining to the manufacture of components weighing from 0.1 grams to 150 tons. We maintain energy consumption within 0.1% and implement fully intelligent process management—all supported by four decades of specialized experience!

Innovation is the foundation of the growth of our group. We have built an open and collaborative innovation ecosystem, partnering with governments, enterprises, universities, and institutions to enable cooperative innovation and shared value, injecting sustained momentum into the industry.<br/>

As an accredited technology enterprise with its own institute and talent academy, SUNFUN has completed more than ten national-level R&D tasks and undertaken major projects commissioned by agencies such as the NDRC, MOST, and MIIT.

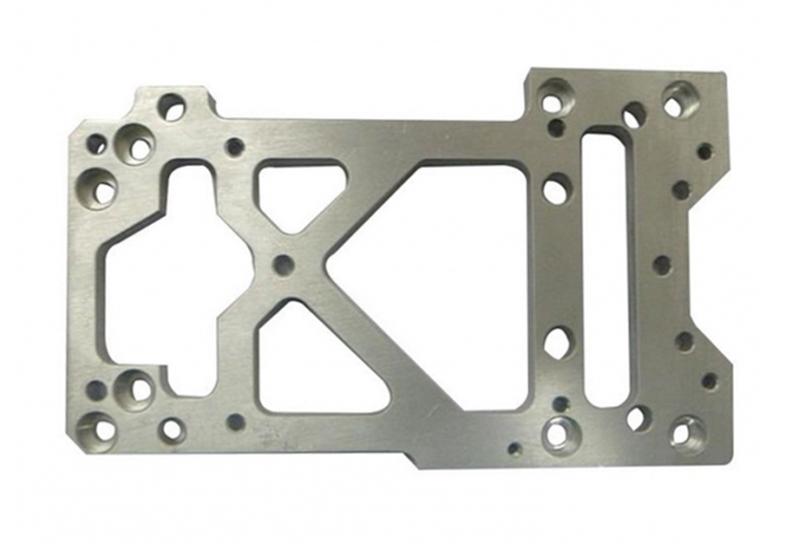

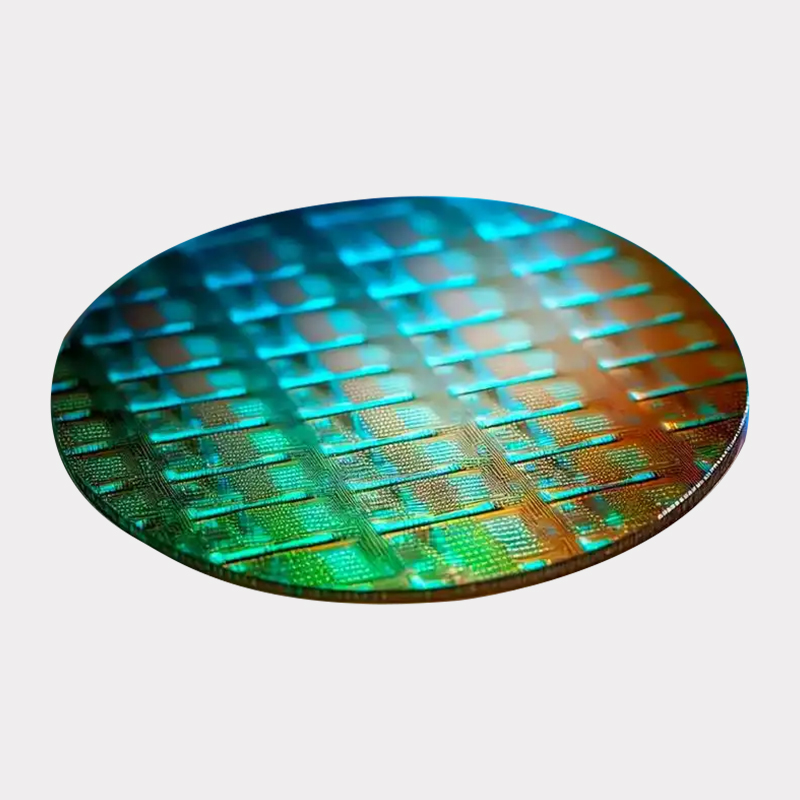

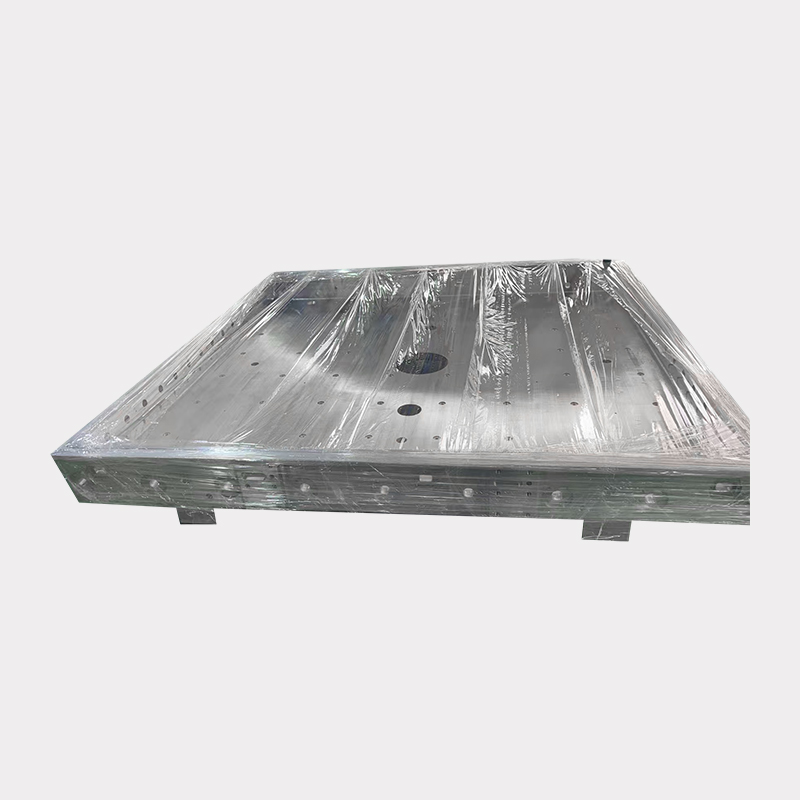

The photovoltaic string welding machine uses infrared heating or laser welding technology to quickly weld the solder-coated ribbon to the main grid line of the battery cell to form a highly conductive series circuit. The photovoltaic string welding machine is mainly composed of a control system, a welding system, a cooling system, and a workbench. Its working principle is mainly to use high temperature to weld solar cells together while ensuring welding quality and efficiency. The welding system is the core part of the photovoltaic string welding machine, including welding heads, feeding devices, and clamps. The welding head melts the ribbon by heating and connects the cells together. The feeding device ensures that the cells can be continuously supplied, while the clamp fixes the cells to ensure that there is no displacement during the welding process. The welding principle of the photovoltaic string welding machine is mainly based on the melting point and thermal conductivity of the metal. During the welding process, the temperature of the welding head is higher than the melting point of the metal, which melts the ribbon, and the thermal conductivity of the cell and the ribbon is similar, so efficient welding can be achieved. The photovoltaic string welding machine has the characteristics of high efficiency, stability, and reliable quality, and can meet the needs of large-scale production. Its application is mainly concentrated in the production link of solar cells, welding the solar cells together according to the design requirements to form a photovoltaic string.

IBC solar cell string welding machine CT-CH-1000 welds 166mmx1/21BC solar cells, and can realize various forms of IBC cell welding. It can meet the requirements of IBC cell (1/2) chamfer welding facing forward and backward, and simultaneously welding front and back of chamfer. Infrared heating, segmented welding; welding temperature and power closed-loop control, temperature rise is gentle, thermal shock is small, and the cell fragmentation rate is effectively reduced. Maximum production capacity: ≤1000PCS/H (with paper feeding mechanism).