SUNFUN Group specializes in intelligent and sustainable industrial development. Driving quality advancement in manufacturing across China and the globe through technological innovation, we are committed to creating green value for a better human life.

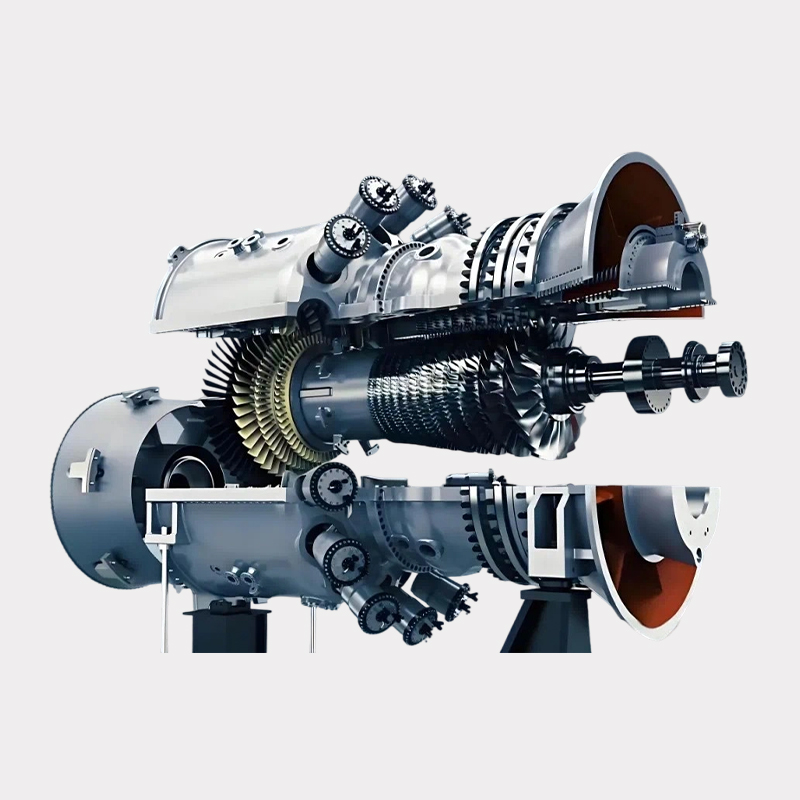

We have deep expertise in smart energy and smart manufacturing, consistently achieving breakthroughs in precision production. Our capabilities range from 0.001-mm precision machining to the manufacture of components weighing from 0.1 grams to 150 tons. We maintain energy consumption within 0.1% and implement fully intelligent process management—all supported by four decades of specialized experience!

Innovation is the foundation of the growth of our group. We have built an open and collaborative innovation ecosystem, partnering with governments, enterprises, universities, and institutions to enable cooperative innovation and shared value, injecting sustained momentum into the industry.<br/>

As an accredited technology enterprise with its own institute and talent academy, SUNFUN has completed more than ten national-level R&D tasks and undertaken major projects commissioned by agencies such as the NDRC, MOST, and MIIT.

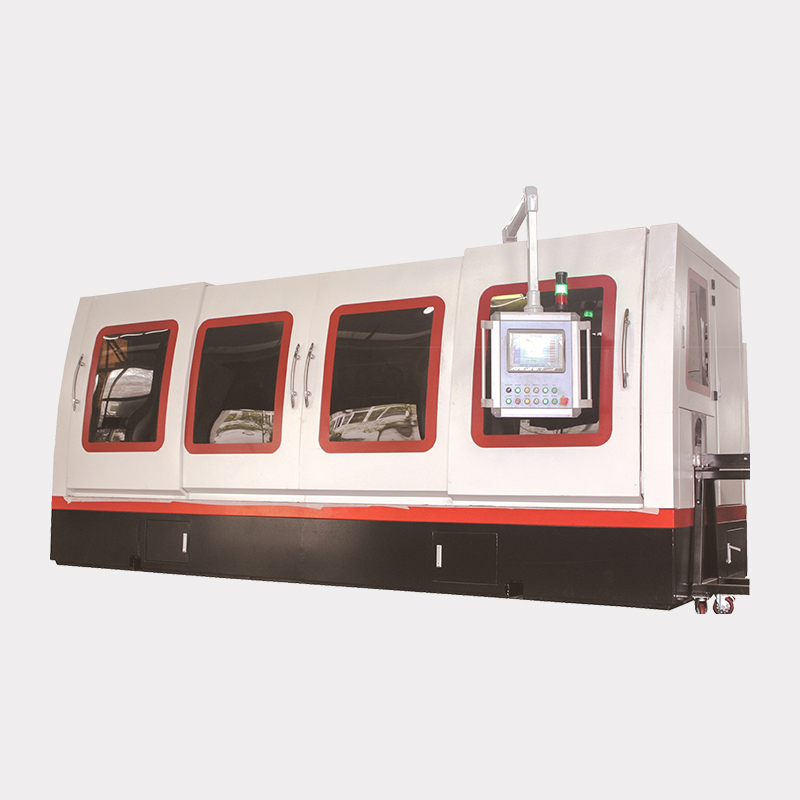

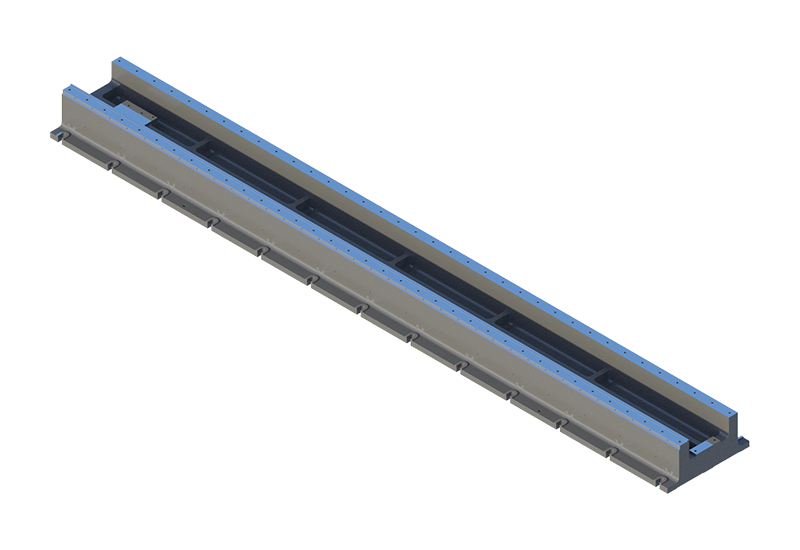

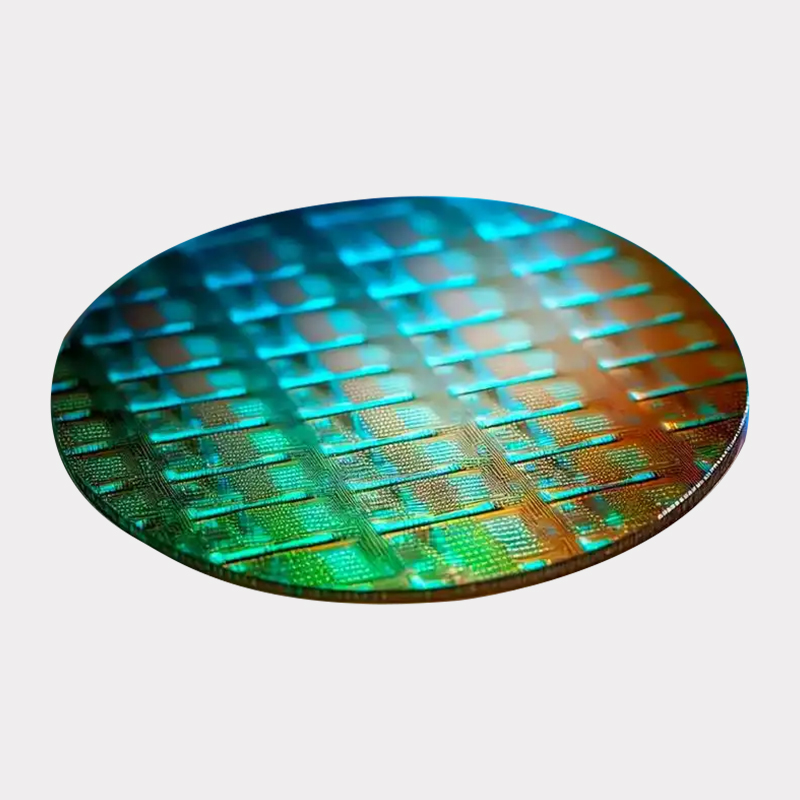

Photovoltaic crystal technology-----After the single crystal silicon is pulled out, the crystal model and longitudinal resistivity distribution are measured. The crystal is fixed on the cutting machine and the crystal is cut horizontally. The head (shoulder) and tail (end) of the crystal should be cut off. The unqualified parts and scraps in the test should be cut off. The parts with longitudinal resistivity exceeding the contract requirements should be disconnected. At the same time, the subsequent process and the machine loading length should be considered and disconnected and matched. The working principle of the cutting and squaring (squaring) process is relatively simple, that is, a high-speed rotating diamond wheel or a steel wire with mortar particles, now a diamond wire, is used to cut and split the crystal horizontally and vertically. When operating, pay attention to the following: (1) The crystal placement position should be tightened and fixed firmly, but the crystal should not be damaged; (2) The cut surface should be as perpendicular to the central axis of the crystal as possible; (3) When cutting, the diamond blade and the crystal contact point should be cooled by water. Wire sand cutting should also be controlled by heat exchange cooling, and the cutting speed and cutting temperature parameters should be matched.

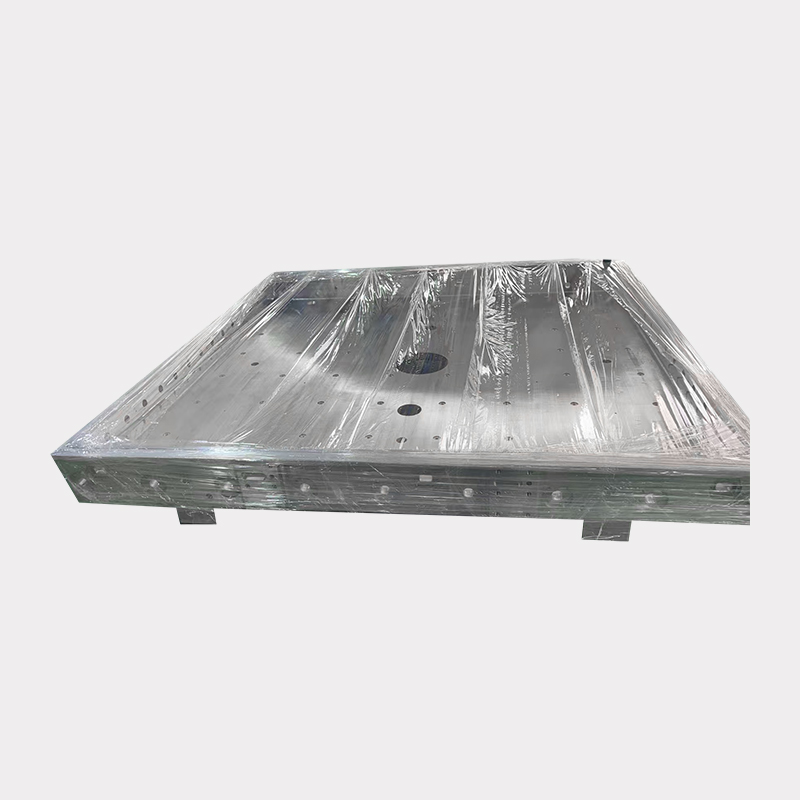

It is a multi-line equipment for cutting single crystal silicon rods. It has a high degree of automation and can automatically complete the loading and unloading, sampling, cutting and other operations of silicon rods. After the cutting is completed, the crystal rods are transported to the discharge table in sections in a dry state by blowing and drying. The cutting tool holder can be raised and lowered individually or as a whole, which is convenient for users to meet different processing requirements and can meet the needs of fully automated production in modern workshops.