SUNFUN Group specializes in intelligent and sustainable industrial development. Driving quality advancement in manufacturing across China and the globe through technological innovation, we are committed to creating green value for a better human life.

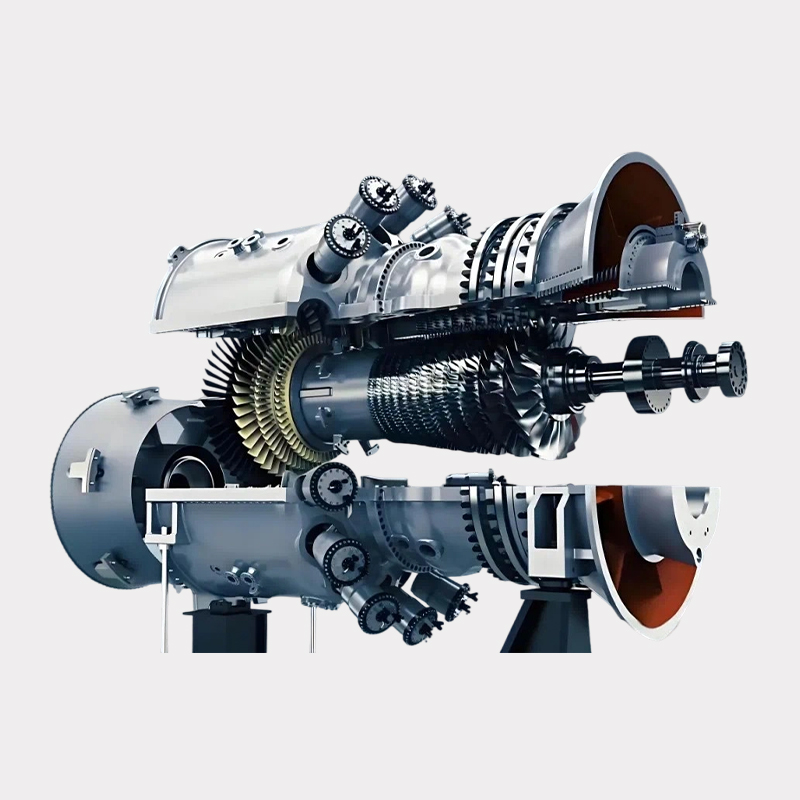

We have deep expertise in smart energy and smart manufacturing, consistently achieving breakthroughs in precision production. Our capabilities range from 0.001-mm precision machining to the manufacture of components weighing from 0.1 grams to 150 tons. We maintain energy consumption within 0.1% and implement fully intelligent process management—all supported by four decades of specialized experience!

Innovation is the foundation of the growth of our group. We have built an open and collaborative innovation ecosystem, partnering with governments, enterprises, universities, and institutions to enable cooperative innovation and shared value, injecting sustained momentum into the industry.<br/>

As an accredited technology enterprise with its own institute and talent academy, SUNFUN has completed more than ten national-level R&D tasks and undertaken major projects commissioned by agencies such as the NDRC, MOST, and MIIT.

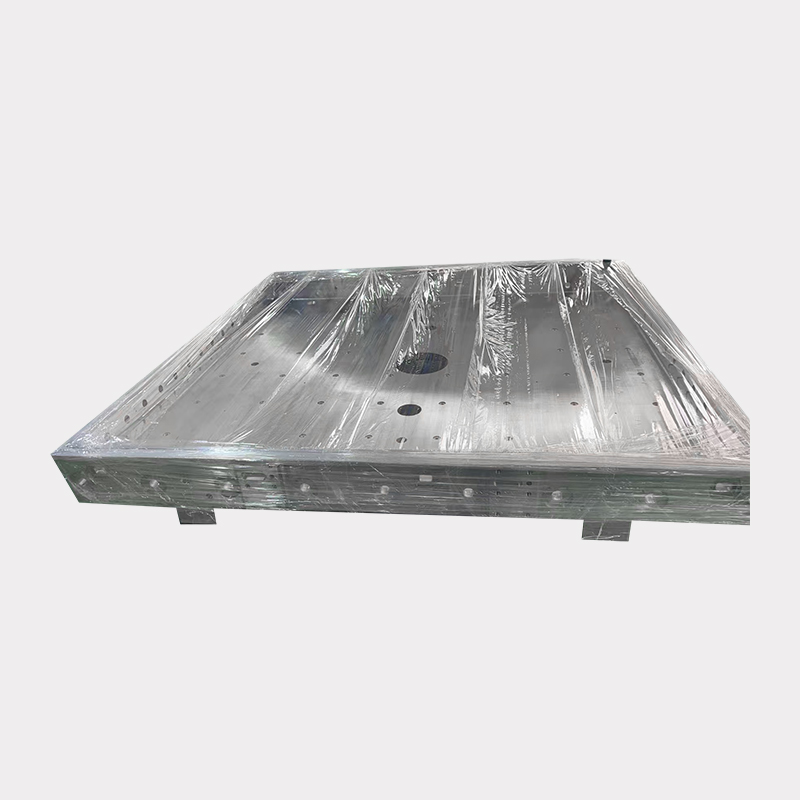

The low-pressure inner cylinder is a key component of the steam turbine. The structural design uses a special material welding method, which is separated from the horizontal plane. The inner cylinder is designed as a double-flow, double-layer cylinder. The use of special materials makes the temperature of the cylinder more reasonable, the deformation distribution is uniform and safe, and has better shock absorption. It also solves the problem of high low-pressure extraction temperature and large inlet steam pressure loss, reflecting the current development direction of steam turbines.

Product Parameters:

The total length of the cylinder is 5300mm*the width is 3294mm*the height is 6435mm. The total weight of the cylinder is 43800kg.

Application Scenarios and Scope of Application:

Steam turbines are the core equipment of thermal power plants. Depending on the size of the model, they can also be used to drive various industrial equipment, such as large fans, water pumps and compressors. On ships, steam turbines are used to drive propellers to provide power.

Product Features/Advantages:

After the electrical revolution, the demand for electricity has been expanding. At present, there are five major power generation methods in my country: thermal power, hydropower, nuclear power, photovoltaic power, and wind power. Thermal power has always been the main type of power generation in my country due to its relatively simple technology, abundant and cheap combustibles, low site selection requirements, and short construction period. And there is a certain space for development.First, The electricity demand brought about by economic growth means that thermal power is still indispensable in the new power generation capacity.Second,The loss of power system stability caused by the increase in the proportion of wind and solar power generation has brought about the demand for peak frequency capacity, which requires the configuration of flexible thermal power units or other energy storage solutions.

Technology and Process:

1: The weld inspection defect level of the cylinder body weld is ISO 5817-B and 5817-C. The inspection area is 100% ultrasonic testing according to SQB49.49 (non-destructive testing of welded joints); 100% surface defect inspection.

2: The cylinder body is welded with carbon steel according to SQZ43.112 <arc welding, tungsten inert gas shielded welding and metal arc welding of carbon steel>.

3: Post-weld heat treatment is carried out in accordance with SQZ43.143 "Technical Specifications for Purchasing of Welded Inner Cylinders and Exhaust Cylinders of Low-Pressure Parts of Steam Turbines".

4: The cylinder body is marked according to the route of the "Steam Turbine Metalworking Process Card", and the CNC boring and milling machine, large drilling, vertical lathe, benchwork and other distributed processes are used for rough and fine processing. After processing, the workpiece is cleaned and rust-proofed before finally entering the final assembly.