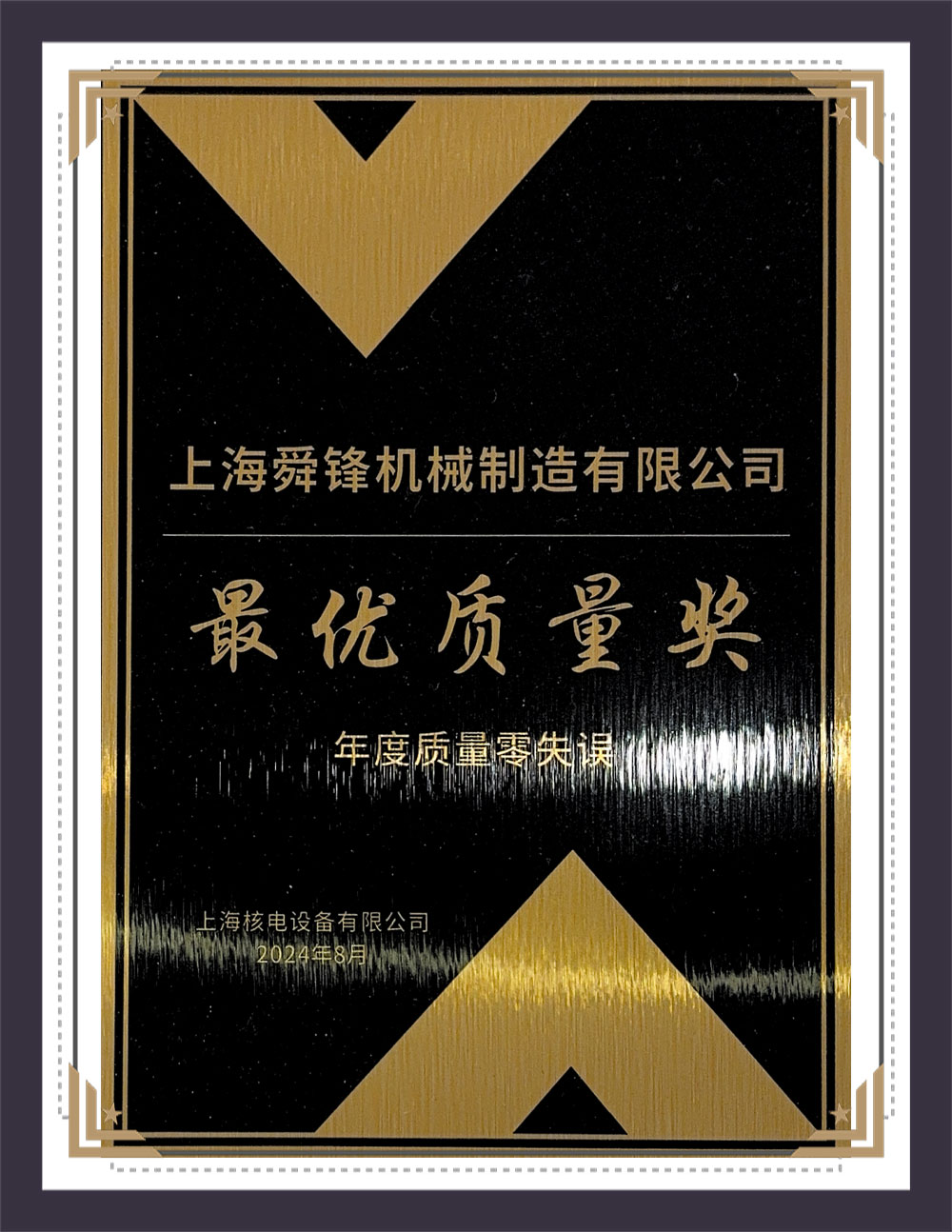

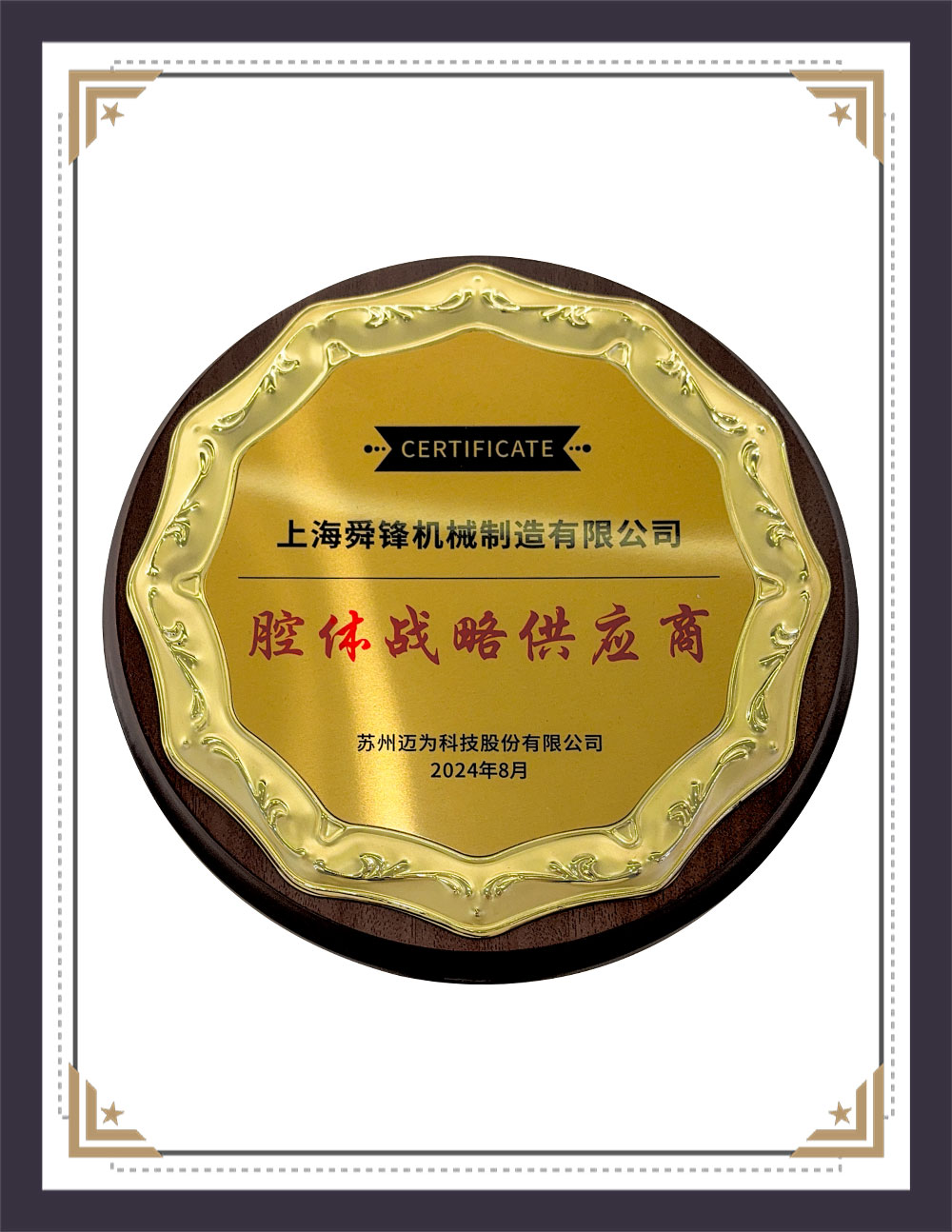

SUNFUN Group specializes in intelligent and sustainable industrial development. Driving quality advancement in manufacturing across China and the globe through technological innovation, we are committed to creating green value for a better human life.

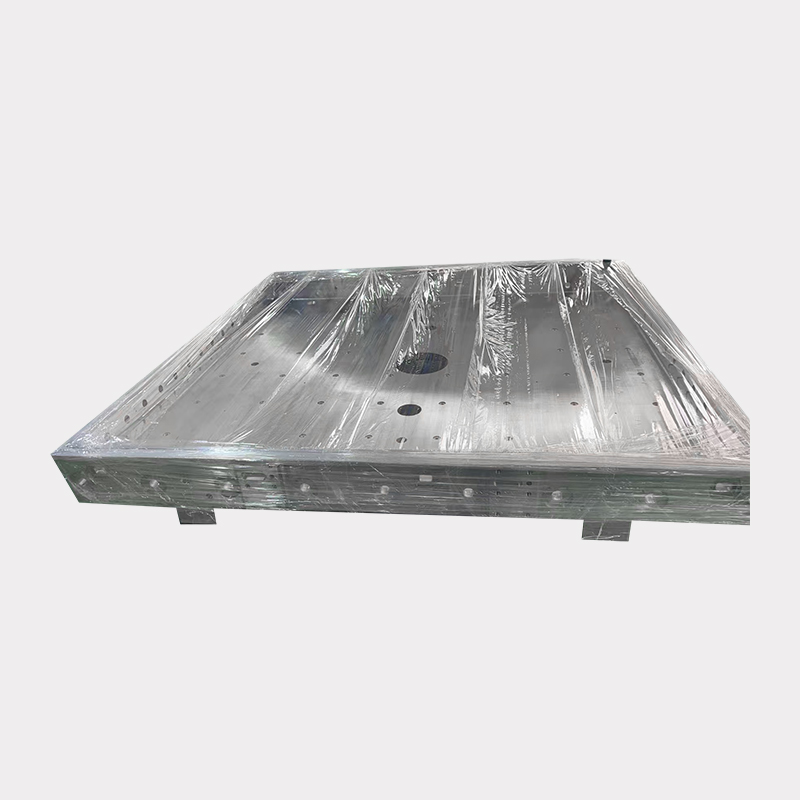

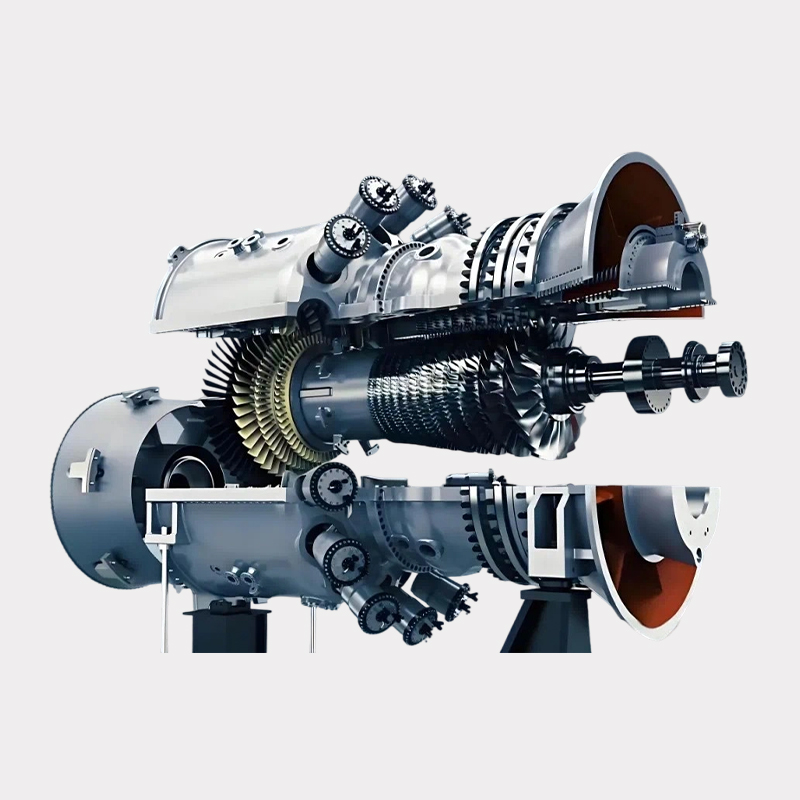

We have deep expertise in smart energy and smart manufacturing, consistently achieving breakthroughs in precision production. Our capabilities range from 0.001-mm precision machining to the manufacture of components weighing from 0.1 grams to 150 tons. We maintain energy consumption within 0.1% and implement fully intelligent process management—all supported by four decades of specialized experience!

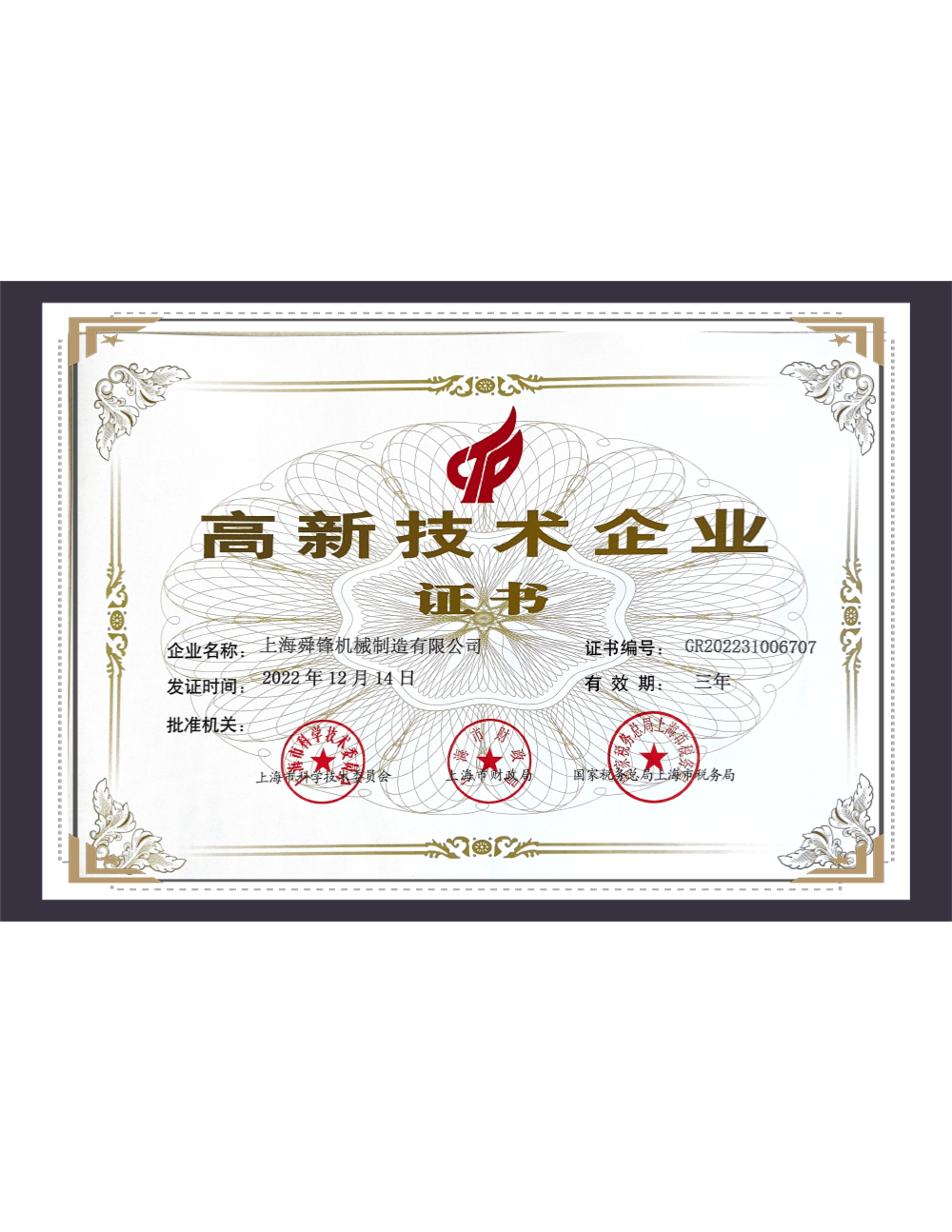

Innovation is the foundation of the growth of our group. We have built an open and collaborative innovation ecosystem, partnering with governments, enterprises, universities, and institutions to enable cooperative innovation and shared value, injecting sustained momentum into the industry.<br/>

As an accredited technology enterprise with its own institute and talent academy, SUNFUN has completed more than ten national-level R&D tasks and undertaken major projects commissioned by agencies such as the NDRC, MOST, and MIIT.

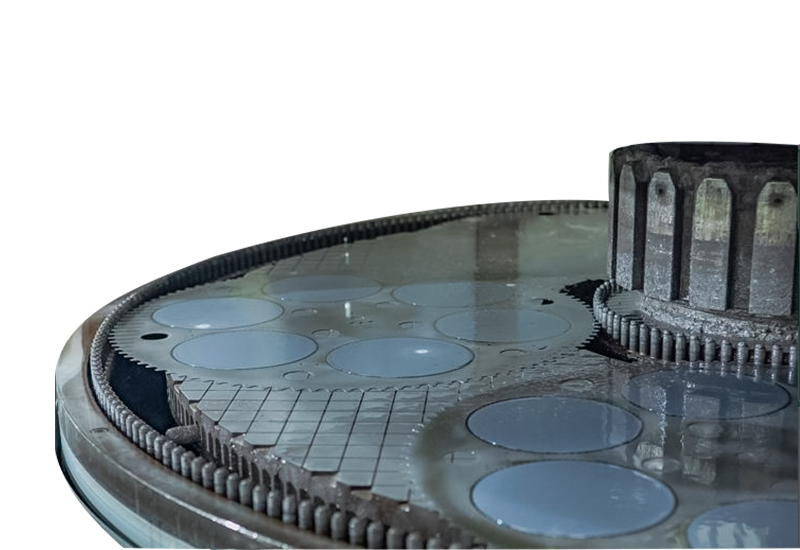

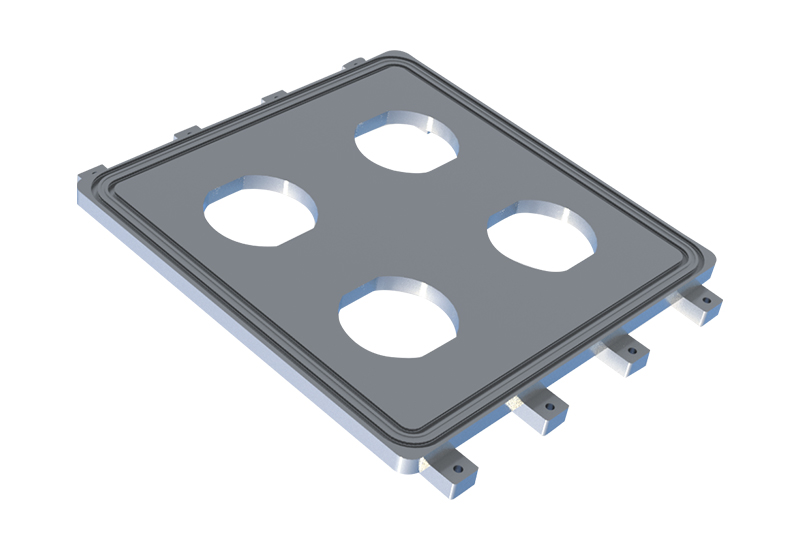

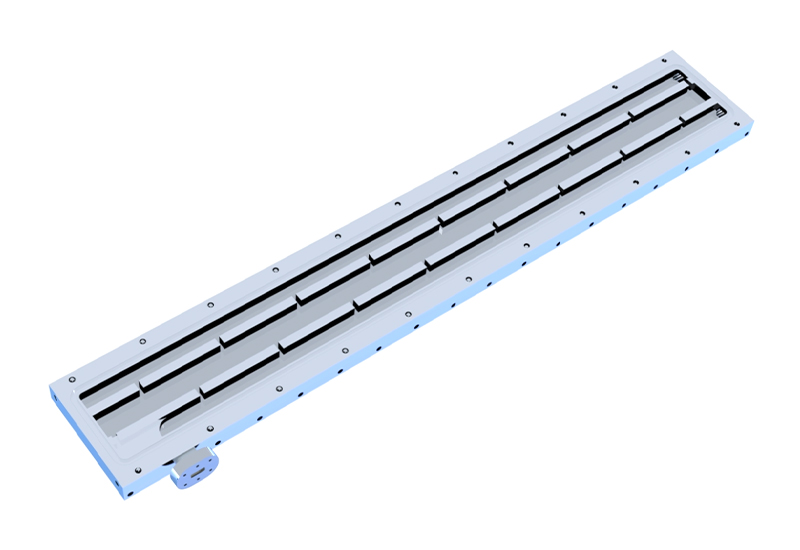

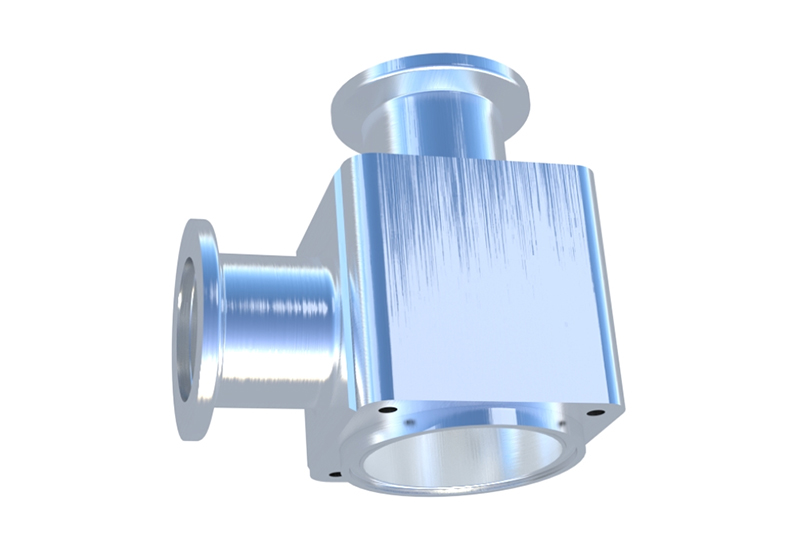

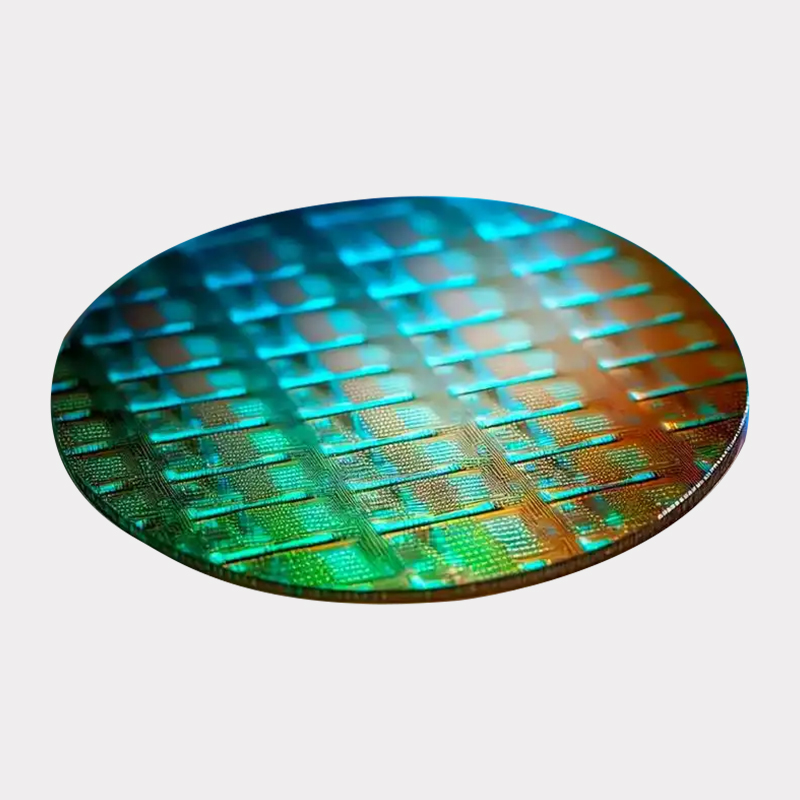

Silicon wafer polishing machine is a kind of equipment specially used for polishing the surface of silicon wafers, which is mainly used in the fields of semiconductor manufacturing and solar cell manufacturing. Its working principle is to grind and polish the surface of silicon wafers continuously through the action of rotating polishing disc and pressure head, making the surface flatter and smoother. At the same time, liquid polishing agent is sprayed to cool the silicon wafer and remove the heat and abrasive debris generated during the polishing process.

It can polish the outer circumference of 8” and 12” wafers. The polishing drum of this equipment is equipped with a fan blade and a lever mechanism. When the polishing drum rotates, the wind resistance acts on the fan blade, driving the lever to swing, so that the force of the polishing cloth attached to the lever pressing on the silicon wafer changes. Therefore, the polishing force can be controlled by controlling the rotation direction and speed of the polishing drum. It can adapt to various edge polishing shapes, improve the operation mode of the robot, and improve the traditional linear walking mode into a rotary motion mode. Multiple robots rotate at the same time to move multiple wafers to the next station in turn. The moving structure of the robot is simplified, the movement is simpler, and the use is more reliable. Improved VN polishing method. The existing method is to place the wafer horizontally for VN polishing. After the improvement, the wafer is placed vertically for VN polishing, which is more conducive to fully filling the polishing position with polishing liquid, and other wafer surfaces are not easy to accumulate liquid. It also has SECS communication and data output functions.