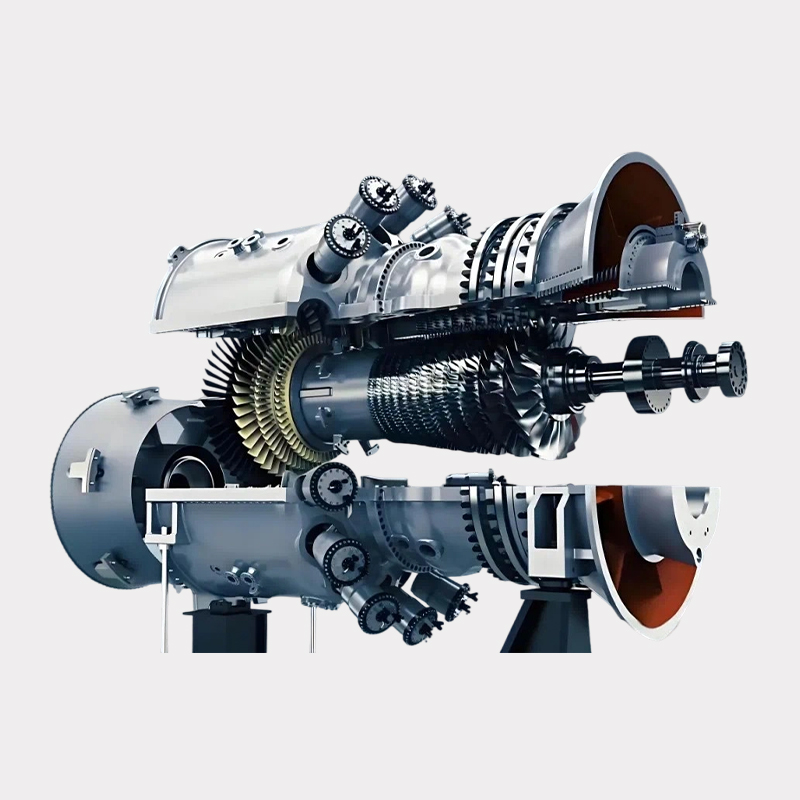

SUNFUN Group specializes in intelligent and sustainable industrial development. Driving quality advancement in manufacturing across China and the globe through technological innovation, we are committed to creating green value for a better human life.

We have deep expertise in smart energy and smart manufacturing, consistently achieving breakthroughs in precision production. Our capabilities range from 0.001-mm precision machining to the manufacture of components weighing from 0.1 grams to 150 tons. We maintain energy consumption within 0.1% and implement fully intelligent process management—all supported by four decades of specialized experience!

Innovation is the foundation of the growth of our group. We have built an open and collaborative innovation ecosystem, partnering with governments, enterprises, universities, and institutions to enable cooperative innovation and shared value, injecting sustained momentum into the industry.<br/>

As an accredited technology enterprise with its own institute and talent academy, SUNFUN has completed more than ten national-level R&D tasks and undertaken major projects commissioned by agencies such as the NDRC, MOST, and MIIT.

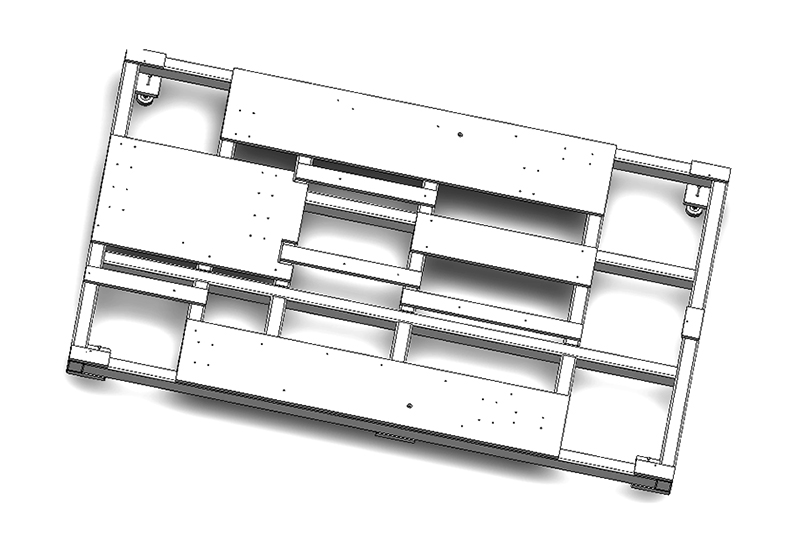

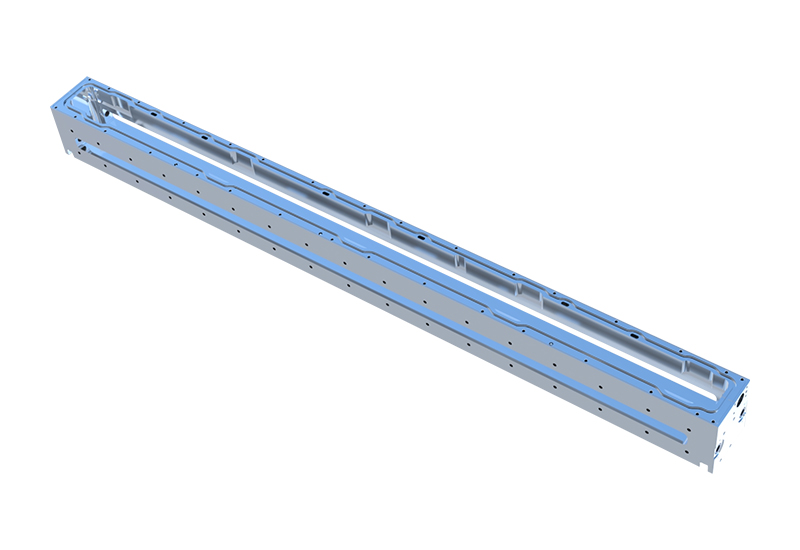

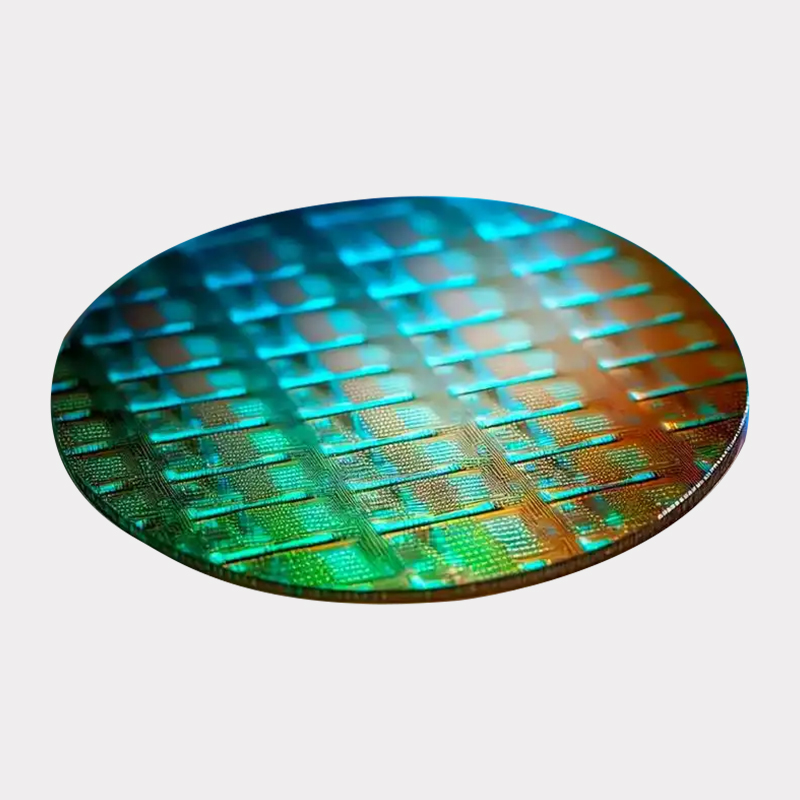

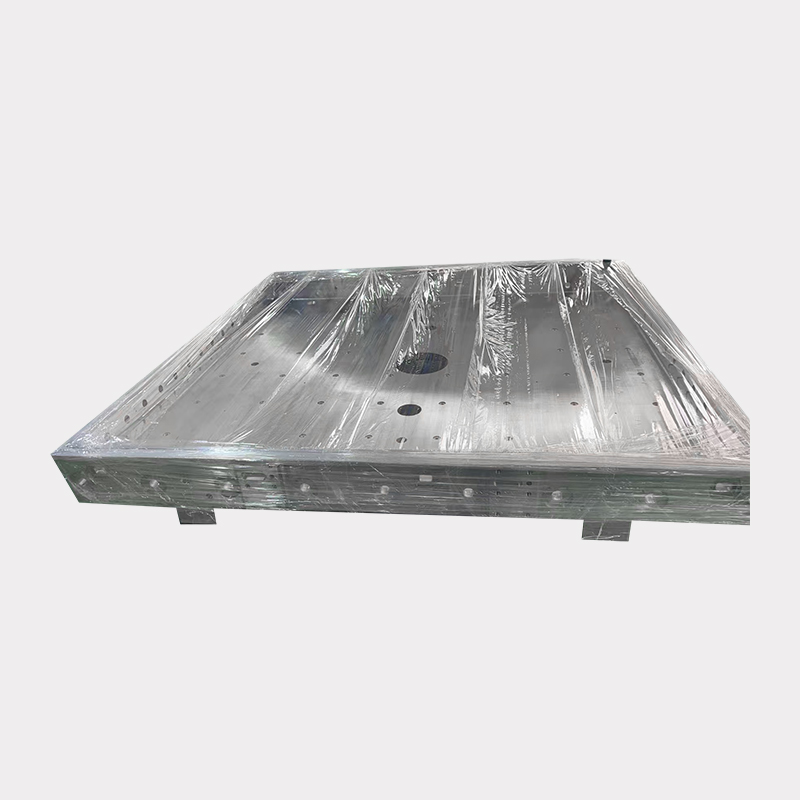

Silicon cleaning machines mainly work based on the principle of combining physics and chemistry. Through a specific mechanical device, the silicon material is driven to roll and vibrate in the cleaning liquid, and physical force is used to remove dust, impurity particles, etc. attached to the surface of the silicon material. At the same time, a suitable chemical cleaning liquid is selected to react chemically with metal oxides, organic matter, etc. that may exist on the surface of the silicon material, and convert them into substances soluble in the cleaning liquid, thereby achieving the purpose of deep cleaning. The high-frequency oscillation signal emitted by the ultrasonic generator of the ultrasonic cleaning machine is converted into high-frequency mechanical oscillation through the transducer and propagated to the medium-cleaning solvent. The ultrasonic wave radiates forward in the cleaning liquid in a sparse and dense manner, causing the liquid to flow and produce tens of thousands of tiny bubbles with a diameter of 50-500μm. The tiny bubbles in the liquid vibrate under the action of the sound field. These bubbles are formed and grown in the negative pressure area where the ultrasonic wave propagates longitudinally, and in the positive pressure area, when the sound pressure reaches a certain value, the bubbles rapidly increase and then suddenly close. When the bubbles close, shock waves are generated, and thousands of atmospheres of pressure are generated around them, destroying insoluble dirt and dispersing them in the cleaning liquid. When the group particles are wrapped in oil and adhere to the surface of the cleaning parts, the oil is emulsified and the solid particles are separated, thus achieving the purpose of cleaning the cleaning parts. In this process called the "cavitation" effect, the closure of bubbles can form a high temperature of several hundred degrees and an instantaneous high pressure of more than 1,000 atmospheres.

This type of equipment is suitable for cleaning and corrosion of silicon materials and phosphorus silicon glass in the solar cell industry. It is also used for cleaning various types of solar cell crystals and polycrystalline silicon wafers such as 100mm*100mm, 125mm*125mm, 156mm*156mm, etc. It adopts PLC control and touch screen operation to realize the whole cleaning process manually and automatically. The whole equipment is made of PP imported from Germany, and the structural design is beautiful and generous. The equipment has a good exhaust system to ensure the health and safety of operators.